Fastener technologies and sealing elements – Discover our product world

The b&m mission: to tangibly improve the interplay of quality, cost efficiency and eco-balance in your components – with high-quality fasteners and sealing systems tailored to your individual application.

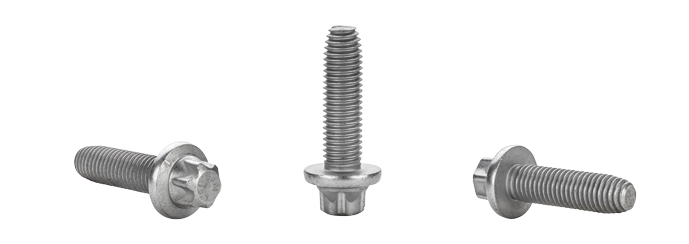

b&m-TRIMSCREW®

Metric screw with additional function for removing coating residues in the thread

Developed to remove coating residues in nut threads, the b&m-TRIMSCREW® is an excellent alternative to screws with a scrape point. It has three recesses that remove paint residue in the thread and consequently prevent interference during the screw-in process. In addition, the dog point geometry supports hole locating during assembly.

b&m-KL PLUG®

Closing and sealing system for bores with and without pressure load

The b&m-KL PLUG® is a one-piece and universally applicable closure and sealing element for bores with and without pressure load. It provides simple and efficient installation without generating waste and can be easily removed in seconds using a standard installation tool.

b&m-HIGHLOAD®

Direct screwing system for high-stress connections

Our b&m-HIGHLOAD® thread-forming screw is primarily used in multi-material construction. The screw is suitable for highly stressed component joints, be they in high-strength steels or in low-strength aluminum alloys. A screw connection with the b&m-HIGHLOAD® is self-locking and free of play. If required, the threads produced are compatible with metric ISO standard parts.

Cold forming for producing screws? Definitely yes! But there’s more. Manufacture ball studs, drive shafts and adjusting spindles up to 10 times faster and with more resource and energy efficiency: With b&m-ECCO TEC® (Ecological Coldforming Technology), we can provide a non-cutting, chipless production method for long-shaft precision parts featuring complex profiles that could previously only be produced by multiple machining steps.

Our services

What drives us are customized solutions for challenges that cannot be overcome using standard market methods. We are with you every step of the way.

Engineering: We are your all-in-one partner

You have components that need to be fastened together – we have the expertise and experience. Fastener verification and validation through application testing, specialized training and design: As technical problem solvers, we, at b&m provide you with advice and support along your entire value chain. Competent. Individual. Pioneering.

Get connected

Production: Non-stop Innovations

What begins its journey as coiled wire has undergone several forming stages before becoming a finished fastener. When it comes to manufacturing, we rely on headers, thread rollers and solar power from the roofs of our b&m buildings. We also use digital features to keep manufacturing processes stable and minimize waste.

Quality: Highest standards for products and processes

All of our certified quality management measures have just one objective: to satisfy b&m’s customers. We are happy to fulfill this requirement – with trained specialists, state-of-the-art metrology equipment and testing methods and the conviction that many small improvements in our company lead to major improvements for you.

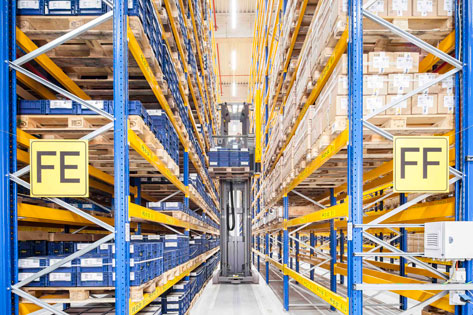

Logistic 4.0: Connecting the supply chain

Based on the fourth industrial revolution, “Logistics 4.0” describes the possibility of networking devices with each other and allowing them to communicate with each other. Collect, pack and deliver: We consistently utilize the digital transformation to combine efficiency with effectiveness and get it on its way to you. Fast. Reliably. Worldwide.

Customized solutions for your industry

Every branch of the manufacturing industry has its own special features. We know the specific requirements and work with you to develop customized solutions.